-

Empty cart

No products in the cart.

Return to Shop

The UK banner printing market serves a wide range of needs, from indoor event graphics in London to long-term roadside banners in Leeds. Understanding where and how your banner will be used helps you narrow providers by specialism, whether you need weather-resistant outdoor PVC, lightweight fabric displays or high-impact retail window graphics.

The banner printing UK market ranges from micro high-street shops running a single eco-solvent printer to national firms operating multiple latex and UV presses. Each technology behaves differently: eco-solvent inks typically need 24 hours to outgas fully, whereas HP Latex prints can be laminated within a few hours. Knowing these differences lets you judge if promised turnaround times are realistic.

Typical Services and Print Technologies

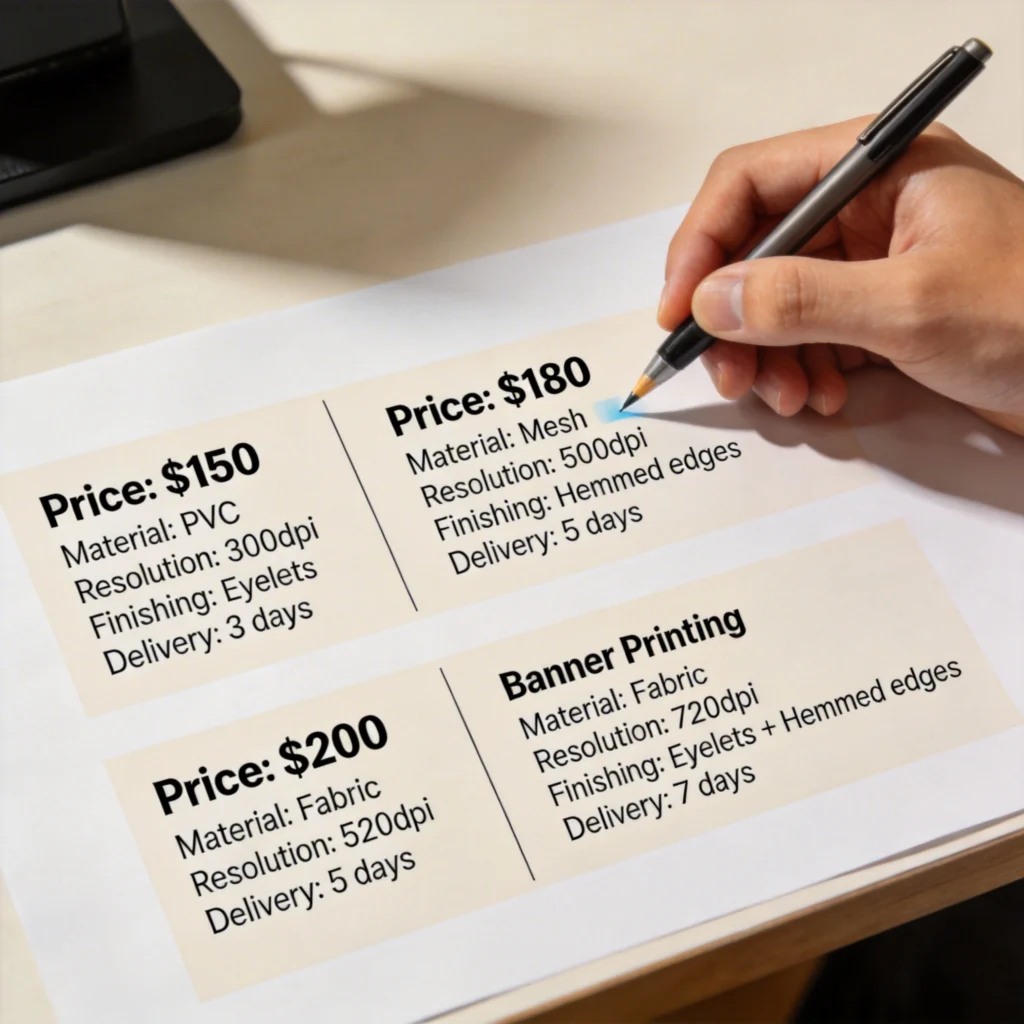

Most UK banner printing providers offer PVC, mesh and fabric banners in widths from 600mm to 3,200mm, with some superwide presses reaching 5,000mm. Entry-level shops often run Roland or Mimaki eco-solvent printers, producing 720–1,440dpi output suitable for viewing distances over two metres. Larger trade houses may add EFI or Durst UV presses for higher volumes and faster drying on heavier materials.

Finishing, Extras and Service Levels

Beyond printing, the market differentiates itself through finishing options, colour management and artwork support. A basic service may include hemmed edges and eyelets every 500mm, while premium providers offer pole pockets, wind slits and stitched hems for long-term outdoor use. Colour-calibrated workflows using FOGRA standards help brand-critical clients maintain Pantone accuracy across multiple campaigns and locations.