Vinyl banners are the workhorses of large-format graphics in the UK—robust, weatherproof and ready for anything from high-street promotions to building wraps. Companies turn to these eye-catching displays for rapid turnaround, vibrant colour fidelity and the freedom to order just one or hundreds without penalty.

Understanding Vinyl Banner Printing UK

Think of your brand as a pebble dropped in water: each banner sends ripples of awareness across busy streets and open fields. A single vinyl banner at a weekend festival can touch thousands of potential customers with zero extra effort once it’s in place.

More than a century ago, big-format signs were produced by hand-cut stencils and squeegee techniques. They delivered impact but demanded hours of setup. Fast-forward to today’s digital inkjet presses, and that same banner can print edge-to-edge in minutes, even if you only need one.

Key Advantages:

- Rapid Customisation: Whether you want one banner or one hundred, setup fees stay predictable.

- High Visual Impact: Full-colour printing that resists fading, even under harsh UV light.

- Weather Resistance: PVC coatings and lamination fend off rain, wind and sun.

- Flexible Sizing: From A3 promos to 6 m façade covers, your design scales without compromise.

Evolution Of Large-Format Printing

Early screen-print pioneers painted stencil by stencil, laying down each hue by hand. While craft-driven, the method tied you to long runs. Digital inkjet changed the game. Tiny droplets of pigment now fire directly onto vinyl at up to 1,440 dpi, dropping setup costs and letting first-time orders compete on price.

Without the need for metal screens or bulky cutting dies, you get:

- Faster proofs

- Lower minimum runs

- Consistent colour across every piece

UK Printing Industry Overview

Below is a snapshot comparing the wider UK commercial printing market against the large-format custom segment. It highlights how banners and signage have stayed strong even as overall revenues dip.

| Segment | CAGR (2020–25) | 2025 Value |

|---|---|---|

| Overall Commercial Printing | -4.1% | £9.2 billion |

| Large-Format and Custom Printing | 1.2% | £1.45 billion |

This table underlines the resilience of large-format print, driven by retail displays, event signage and construction site graphics. Armed with these figures, you can budget more accurately and negotiate lead times with confidence.

Partnering with a local specialist like Banner Printing Ltd brings in-house preflight checks, free UK delivery and eco-friendly PVC-free options. That way, your artwork arrives ready for press—no hidden fees, no last-minute surprises.

Key Takeaways And Next Steps

Vinyl banner printing in the UK blends a rich heritage of craftsmanship with modern inkjet efficiency. This combination supports both single-test designs and large-scale campaigns without breaking the bank.

Practical Steps:

- Gather Artwork: Verify resolution, colour mode and bleed areas.

- Compare Quotes: Look at setup charges, finishing options and delivery terms.

- Plan Installation: Choose grommets, pole pockets or reinforced hems based on where you’ll display.

- Confirm Timeline: Align proof approvals, production slots and your free UK shipping window.

Follow these steps to move smoothly from concept to street-side display and make each banner count.

Why Choose Local Suppliers

Working with a UK-based print partner slashes transit times and trims carbon miles. Local teams—including designers, press operators and packers—sit under one roof, so communication stays sharp and mistakes get caught early.

Banner Printing Ltd in Manchester offers:

- Free UK delivery on all orders

- Three-step preflight checks in-house

- Eco-friendly PVC-free media and low-VOC inks

When you choose local, you gain speed, clarity and a more sustainable approach—everything you need to get your message noticed.

"A well-designed vinyl banner spreads your message like ripples, growing brand recognition with every view."

Start planning today to make your brand impossible to miss. Guaranteed.

Vinyl Banner Materials And Finishes

Vinyl banners pop up across the UK—from high-street shopfronts to festival grounds. They frame promotions, guide crowds, and turn bare walls into billboards.

Think of PVC vinyl as a trusty raincoat for your graphics: it locks out moisture, fights fading and delivers vibrant colour that stands up to wind and rain.

By contrast, mesh banners behave like your favourite sportswear—light, breathable and designed to let wind pass through. Cutting banner weight by 40%, they make rigging faster and reduce stress on fixings.

- PVC Vinyl: Smooth surface, robust weatherproofing, bold print quality

- PVC-Free Textile: Soft touch, fully recyclable, perfect for green-minded events

- Mesh Banners: Airflow-friendly, wind-resistant, good colour reproduction

- Blockout Finish: Double-layer barrier blocks light bleed, adds privacy

- Reflective Coating: Embedded glass beads boost night-time visibility

Comparing Material Trade-Offs

Choosing between vinyl, mesh or textile often comes down to balancing strength, weight and sustainability. Here’s a quick snapshot:

| Material | Durability | Weight | Eco Impact |

|---|---|---|---|

| PVC Vinyl | High | Medium | Low |

| PVC-Free Textile | Medium | Low | High |

| Mesh Banners | Medium-High | Low | Medium |

PVC vinyl shines outdoors but carries a larger environmental footprint. PVC-free textiles slash waste and appeal to eco-savvy organisers.

"Mesh banners strike a balance between visibility and wind resilience, ideal for UK outdoor marketing."

Construction firms often pick mesh on windy sites to avoid ripped banners and re-hangs.

Specialty Finishes Explained

Sometimes base materials need an extra boost. That’s where specialist coatings come in.

A blockout finish sandwiches an opaque layer in your banner to kill light bleed—ideal for shop windows or backlit displays.

By contrast, reflective coatings mix glass beads into the vinyl, bouncing car headlights and street lamps directly back at drivers.

- Use blockout banners when you need privacy or sharp backlighting control

- Choose reflective finishes for roadside events and night-time promotions

- Install mesh banners on scaffolding or fence lines in exposed, windy areas

- Select PVC-free textile at indoor exhibitions to tick sustainability boxes

UK regulations and new ink technologies are reshaping print choices. Trade sources note a rise in water-based and low-VOC inks for indoor work, plus growing interest in recyclable textiles. Discover more insights about digital printing trends with MTA Digital.

Check out our guide on mesh versus PVC banners in the UK for a deeper dive.

How To Choose The Right Material

First, map out your environment: is it a blustery building site or a calm conference hall?

- Go for PVC vinyl if you need rock-solid, weatherproof banners with punchy colours outdoors

- Pick mesh when wind load is a worry and you can accept a touch of print diffusion

- Opt for PVC-free textile at indoor events where texture and recyclability matter

Banner Printing Ltd supplies every material and finish, complete with in-house preflight checks to ensure your banners perform exactly as planned.

Standards And Compliance

Before your banner goes up, UK rules demand fire-retardant and safety approvals:

- Fire-Retardant Ratings like BS 5867 mean safe use in public venues

- Material Certifications such as EN 71 compliance minimise chemical exposure

Understanding how each material and finish impacts durability, weight and eco credentials helps you specify the perfect vinyl banner every time.

Talk to our team for personalised advice on choosing the right banner today.

Choosing Banner Sizes And Mounting Methods

Picking a banner size is a bit like choosing a made-to-measure suit. Too small and your message fades into the background; too large and you’ll be wrestling with fixings. Your design has to slot into the space you have, whether it’s a hall wall or an outdoor fence.

A 3 m × 2 m backdrop at a trade show, for instance, demands careful attention to bleed and safe zones. If logos sit too close to the cut line, they risk vanishing when the banner’s trimmed.

- Standard sizes such as A1, A0, 1 × 2 m and 2 × 3 m help you breeze through proofs.

- Custom dimensions adapt to unusual facades or creative installations.

- Bleed (usually 5 mm) extends artwork beyond the trim, so you won’t get white slivers along the edge.

- Safe zones keep crucial text and graphics at least 10 mm inside the cut line.

Measuring And Scaling Artwork

Getting your artwork sized correctly means you won’t end up with fuzzy graphics or stretched logos. Stick to vector files for logos and aim for high-resolution raster images (150–300 DPI) if you’re using photos or detailed illustrations.

It’s tempting to scale up a small file, but that often leads to pixelation. Plan your artwork dimensions in step with your chosen banner size to keep lines crisp and edges sharp.

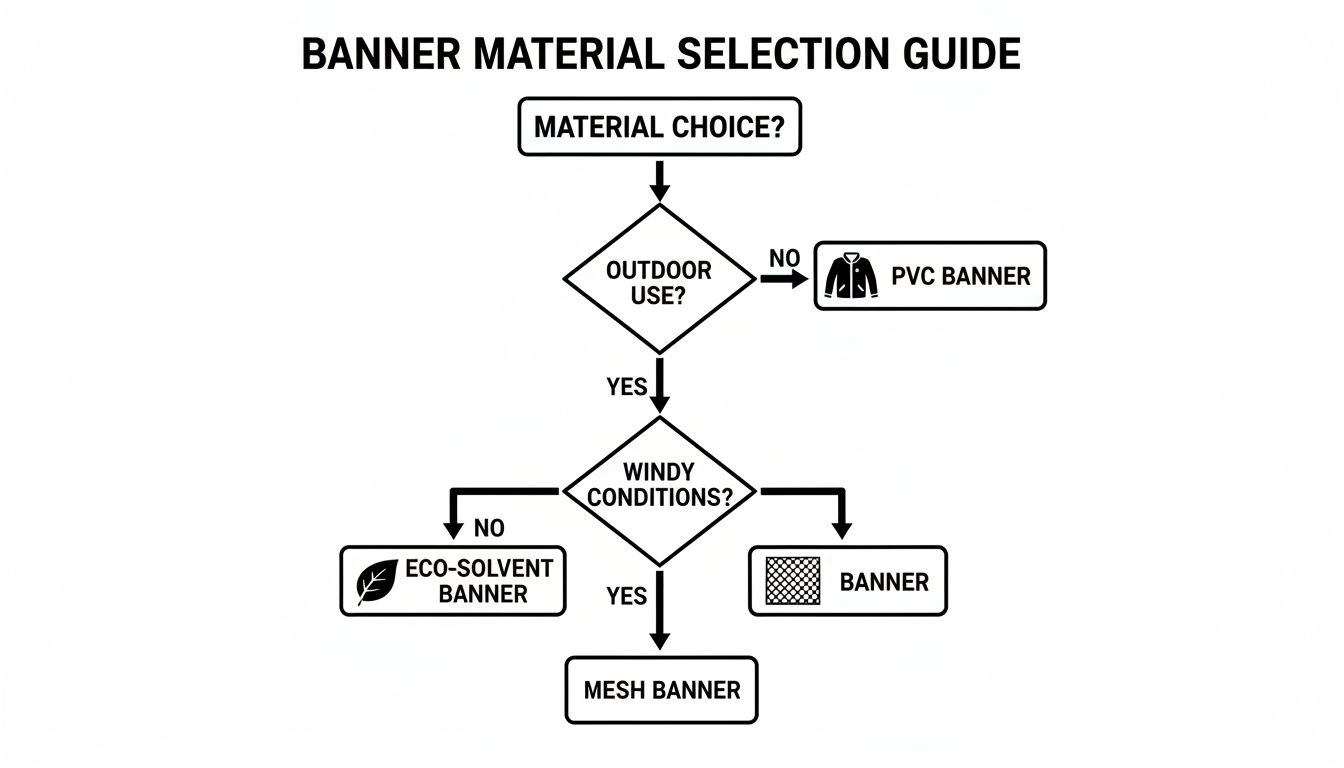

That chart sums it up neatly:

- PVC banners tackle heavy-duty outdoor work.

- Eco options fit indoor events and promotions.

- Mesh banners shine on windy sites where airflow matters.

For a deep dive into shapes, sizes and materials, see our Event backdrop banners in the UK materials dimensions design inspiration guide.

Selecting Mounting Options

Your choice of fixings can make—or break—a smooth install. Match your method to the surface at hand, whether you’re hanging on brick, steel or a tension frame.

- Grommets with reinforced hems suit outdoor walls and scaffolding.

- Pole Pockets slide over poles for quick setups at exhibitions.

- Magnetic Strips attach to metal surfaces without drilling.

- Hooped Hems hook into tension frames or roller systems.

“Picking the right mounting method prevents banner damage and reduces installation time,” advises a UK event manager.

From grommets on building façades to pole pockets in shopping centres, each scenario has its ideal solution.

Practical Decision Tree

Follow these four steps and you’ll land on the perfect combination:

- Identify your surface type (brick, metal, frame).

- Assess weight and wind exposure at your location.

- Match mounting style to the environment and attachment points.

- Confirm your budget for materials and labour.

This approach ensures a tidy, professional finish with minimal on-site tweaks.

Common Mistakes To Avoid

Cutting corners here costs time and money. Watch out for these pitfalls:

- Overloading grommets on windy banners, leading to ripped hems.

- Ignoring safe zones and ending up with chopped-off logos.

- Skipping precise site measurements—hello, costly reprints.

Double-check your dimensions, bleed settings and mounting strength before you hit ‘print’. That way, your banner will nail its first—and only—install.

Mastering Design And File Preparation

Vinyl banner printing in the UK hinges on precise file preparation. A solid prepress routine cuts back on unexpected delays and ensures your banners pop with the right colours.

Putting in that groundwork—from colour management to bleed settings—means your print proofs match your screen every time.

Colour Workflow Essentials

Moving from screen to press often throws up surprises in how colours appear. On-screen RGB images get translated into CMYK, which handles smooth gradients. At the same time, Pantone spot inks lock down exact brand shades.

If you want absolute consistency, convert those spot swatches into CMYK equivalents. And don’t forget: a properly profiled monitor brings what you see on screen closer to the final print.

Setting Bleeds And Safe Zones

Think of bleeds as the extra canvas beyond your design’s edge—just in case the cutter drifts. We recommend a 5 mm bleed all around; that prevents those panic-inducing white slivers.

Equally important are safe zones. Keep any key text or logos at least 10 mm inside the cut line and you won’t accidentally chop off a headline.

- Bleed Margin: Extend your artwork by 5 mm on each side.

- Safe Zone: Position logos and text 10 mm from the trim.

- Trim Line: Use on-screen guides to mark cut paths clearly.

- Background Colours: Avoid matching your crop marks to stop confusion.

These steps catch layout issues early and minimise reprints.

Comparing File Formats And Compression

Picking the right format makes a big difference. A PDF/X-1a file bundles your fonts and images into a single, print-ready package, meeting most industry specs.

If colour fidelity is critical, PDF/X-3 supports embedded ICC profiles—though it can bulk up file size. Your designer might also choose EPS or AI for native vector flexibility, but remember: PDFs are still the most widely accepted.

| Format | Pros | Cons |

|---|---|---|

| PDF/X-1a | Guaranteed print compliance + embedded fonts | Larger file sizes |

| PDF/X-3 | ICC colour profiles + high graphics fidelity | Some RIPs need conversion |

For specialised jobs, you can always send along an EPS or AI file with text outlined as a backup.

Embedding Fonts And Exporting PDF

Nothing derails a print run faster than missing fonts. Embed your fonts or convert text to outlines if licensing gets tricky.

When exporting, use high-quality print presets with lossless compression. That way, every detail stays crisp.

This screenshot flags any unembedded fonts (in red) and images under 150 DPI (in yellow), so you can fix issues at a glance.

Before you hit upload, tick these off:

- Confirm colour mode is CMYK for print.

- Verify that bleeds and safe zones match your template.

- Embed all fonts or outline your text.

- Check image resolution sits between 150–300 DPI.

- Flatten transparencies and outline vector elements.

“Accurate preflight checks cut proofing time by up to 50%, keeping your banners on track.” – Banner Printing Ltd

Following this checklist streamlines approvals and gets your project moving smoothly.

For step-by-step artwork submission, see our guide on Uploading Artwork for Custom Banners.

That covers design and file prep. With these fundamentals in place, your vinyl banner printing in the UK will flow seamlessly from digital proof to final display.

Evaluating Pricing And Delivery Timelines

Getting a grip on costs and delivery slots early lets you set realistic budgets and deadlines. Material choice, print resolution, finishing options and order volume all play a part in the final price tag.

- Material Type: Heavier or specialised vinyl pushes up the unit cost.

- Print Resolution: Higher dpi eats more ink and may require extra file prep.

- Finishing: Lamination, hems and fixings add labour and materials.

- Order Volume: Bulk orders usually unlock volume discounts per banner.

Key Cost Drivers

Picking a heavyweight PVC vinyl, for instance, will bump up your baseline dramatically. It’s tempting for durability, but you’ll pay for that extra robustness.

Moving from 720 dpi to 1440 dpi sharpens your visuals, yet it can add a noticeable percentage to your ink spend. Decide if that crispness is worth the trade-off.

Adding blockout or laminated finishes adds a few pounds per metre. It’s ideal for double-sided displays or outdoor protection, but factor in that extra labour cost.

Finally, if you order in bulk—say, more than 20 m²—you often see the per-unit price drop by 20–30%. That can make a huge difference for recurring campaigns.

Key Insight: Demand for printed vinyl in the UK is growing at a 5.29% CAGR through 2035, according to Spherical Insights.

Typical Lead Times

Most small banner runs with standard materials leave the press within 24 hours. If you need banners by tomorrow, next-day services will have them ready in 1 business day.

Below is a quick look at typical cost brackets and production times in the UK:

Introducing our “Pricing And Turnaround Options” table, so you can match your budget and timeline at a glance.

Pricing And Turnaround Options

| Service Level | Price Range | Turnaround Time |

|---|---|---|

| Same-Day | £30–£60 | Same day |

| Next-Day | £25–£50 | 1 business day |

| Standard | £15–£30 | 2–3 business days |

| Bulk Orders | £10–£20 | 4–7 business days |

Use this as a starting point, then tweak based on your material and finishing choices.

Reducing Delays

Jump-starting production is all about preparation. First, send print-ready files with correct bleed and safe-zone margins. Then, ask for proofs as soon as you upload your artwork.

• In-house preflight checks catch glitches before they escalate.

• Rapid proof approvals keep your order at the front of the queue.

• Consolidating similar orders slashes setup time and can qualify you for bulk pricing.

Value Of Free Shipping

Free UK delivery on every order means no hidden carriage costs. All packages ship from Manchester via a tracked courier, complete with insurance.

• Zero carriage fees for UK addresses.

• Faster restocks for repeat orders—still free.

• Eco-friendly packaging to cut waste and carbon miles.

If your campaign is urgent, express courier upgrades start at just £5.

Balancing Cost And Speed

Start by fixing your project timeline and budget. Combine bulk rates with free UK delivery to secure the best deal. Then, approve proofs quickly and stick to preflight guidelines to fast-track production.

Booking installation in advance ensures our team can handle on-site frame building and tensioning without a hitch.

Banner Printing Ltd pulls all these threads together under one roof in Manchester. Our tight-knit crew handles everything—preflight, printing, finishing and dispatch—so most orders ship within 24–48 hours.

Pro Tip Booking your print slot at least two weeks ahead locks in the best pricing and secures your preferred delivery window.

Key Takeaways

- Compare service levels to hit both your deadline and budget.

- Use in-house preflight checks to avoid costly proofing delays.

- Factor in free UK delivery and on-site installation for a smooth rollout.

By understanding pricing tiers, lead times and delivery options, you’ll plan a vinyl banner project that hits the mark without surprises.

Get a free quote today from Banner Printing Ltd and secure your banners ahead of key promotional dates.

Visit Banner Printing Ltd to view detailed pricing and upload your artwork instantly. Our UK support team is on hand Monday to Friday.

Installing Vinyl Banners And Use Cases

Proper installation ensures your vinyl banner isn’t just eye-catching—it stays put through wind, rain or shine. Think of it like tuning a drum: get the tension right and the impact lasts; slack it off and you risk sagging or splits. We’ll guide you through prepping brick walls, mounting on metal frames and working with tension-fabric structures so every banner you hang looks as crisp as a newly printed page.

When you know how to reinforce edges and manage wind loads, you’ll slash tears, cut down on reprints and save money over the life of the banner. Stick around for three UK-based case studies that bring these techniques to life.

Quick Insight: Proper mounting can extend banner life by up to 30%, reducing reorders and labour costs.

Site Preparation Tips

Begin by assessing the surface type and its load-bearing capacity. A brick wall is like rough terrain—it needs sturdy anchors. A steel frame is smoother; magnets or straps work brilliantly. Fabric tension systems demand exact measurements, almost like tailoring a bespoke suit.

- Masonry Anchors: Drill pilot holes, insert plastic plugs and secure grommets.

- Magnetic Strips: Perfect for smooth metal surfaces—no drilling required.

- Cable Ties: Pair with reinforced hems on mesh banners to spread stress evenly.

On softer frames—or with tension-fabric setups—calculate anchor loads carefully. Too loose and the banner droops; too tight and the edges might tear. Next, let’s tackle those blustery spots.

Securing Banners In Windy Zones

Wind can turn a taut banner into a flapping sail. Reinforcing stress points stops small gusts from becoming costly rips.

- Wind Slits: Cut these into larger banners to let air pass through.

- Corner Patches: Sew on extra fabric where strain peaks.

- Edge Tape: Line the long sides to stiffen against whipping.

When installing at height, space your grommets no more than 300 mm apart. This simple tweak can boost holding power by up to 40%. Now, let’s see these tips in action.

Real World Case Studies

A high-street café in Manchester swapped its old sign for a fresh PVC vinyl banner fixed with magnets. After a thorough brick clean and magnet-strength test, the display stayed pristine through winds up to 35 mph, cutting rehangs by 100%.

At a summer festival, organisers wrapped mesh banners around scaffold frames near the main stage. They added wind slits every 1 metre and reinforced all hems. The result? A flawless appearance, even in gusty conditions.

A London corporate conference chose tension-fabric frames with sewn-in pole pockets. The lightweight, PVC-free textile was fully recyclable, and telescopic poles meant a perfect fit first time—thanks to a detailed preflight check.

Why Partner With A Full-Service Provider

Opting for a UK-based, full-service printer removes the guesswork. Banner Printing Ltd ships most orders in 24–48 hours, offers free UK delivery and performs in-house preflight checks to keep your project on track.

- Eco Options: PVC-free materials and low-VOC inks.

- Expert Support: Advice on site prep and mounting for any surface.

- All-In-One Workflow: From digital proof to dispatch under one roof.

Ongoing Maintenance Advice

Treat your banners like fine leather—regular care keeps them looking sharp.

- Check all fixings monthly and tighten any that loosen.

- Apply a UV-protectant spray once a year to guard against fading.

- Roll banners for storage to prevent creases.

Book your installation slot today and let us handle the heavy lifting.

Contact our support team for bespoke advice, a no-obligation installation quote and scheduling assistance now.

Frequently Asked Questions

Find clear, practical answers to the queries we hear most about vinyl banner printing in the UK. These tips will help you steer clear of surprises, delays and hidden costs.

Typical Lead Times For Small And Bulk Vinyl Banner Orders

Small runs (1–2 banners) often ship within 24 hours when you choose standard PVC vinyl and finishes.

For larger batches or bespoke sizes, plan on 3–5 business days, depending on volume, coatings and courier options. Quickly approving proofs and running our preflight checks can cut your turnaround by up to 50%.

Choosing Between PVC And Eco-Friendly Banner Materials

PVC banners offer sturdy, weatherproof performance outdoors.

Eco-friendly PVC-free or textile alternatives reduce waste and suit short-term indoor use.

We recommend weighing up exposure, lifespan and budget before you decide.

File Formats And Resolutions

What File Formats And Resolutions Guarantee Print Quality?

We ask for vector files (EPS, AI or PDF) or high-res images at 150–300 DPI at final size. Always work in CMYK and embed your fonts. Our in-house preflight tool flags missing links or low-resolution artwork before it goes to press.

| Format | DPI Range |

|---|---|

| Vector | N/A |

| Raster | 150–300 |

Ordering Custom Sizes And Shapes

Yes—custom dimensions and cutouts are no problem. Simply supply exact measurements and a dieline file. Bear in mind that unusual formats may carry extra costs and slightly longer lead times.

Ideal Eyelet Spacing For Banner Mounts

Standard eyelet spacing is 300 mm along the edges for balanced support.

In windy locations or with heavier banners, tighten this to 200 mm centres to reduce stress. Always double-check that your fixings suit the surface you’re mounting to.

“A precise dieline stops surprises and keeps your project on budget”

Banner Printing Ltd team

Ready to get your vinyl banner printed fast? Contact Banner Printing Ltd now to upload your artwork and enjoy fully hassle-free UK delivery today.

One Comment

[…] making the switch can be a great way to reinforce your brand’s green credentials. Our guide to vinyl banner printing in the UK dives deeper into why this classic material is still so reliable for many […]