Thinking of starting a windows decals business? You're in the right place. It's a fantastic way to jump into a creative, profitable market, turning plain glass into prime advertising space or stunning decorative art. Getting it right, though, means mastering the entire craft—from picking the perfect vinyl to delivering a flawless finish for local shops, offices, and events.

Your Roadmap to a Thriving Decals Business

Welcome to your complete, no-fluff roadmap for building a successful window decals business from the ground up. We're moving past the theory and diving straight into the practical steps and real opportunities in the UK's bustling print and signage market.

Demand for window graphics—both temporary and permanent—is seriously strong. Think about it: retailers need them for promotions, offices need them for branding, and everyone wants them for seasonal decorations.

The numbers back this up, too. The UK window film market, which covers everything from branding decals to promotional displays, was valued at USD 140.23 million in 2023. It’s set to rocket to USD 281.5 million by 2035, which tells you this is a healthy, growing industry with plenty of room for new players. You can dig into the market projection details to see the full growth potential for yourself.

Consider this guide your strategic blueprint. We’ll walk through every core pillar you need to put in place to turn a great idea into a profitable reality.

Key Stages of Building Your Decals Business

To get this right, you need a clear picture of the journey ahead. The whole process can be broken down into a handful of manageable stages, each with its own focus and goals. This structure helps you build on solid foundations, setting you up for growth from day one.

Here’s a quick glance at the essential steps we’ll be exploring in detail.

| Stage | Key Focus | Primary Outcome |

|---|---|---|

| Foundation | Materials & Equipment | Smart initial investment in the right vinyl, printers, and cutters. |

| Production | Workflow Mastery | An efficient, repeatable process for high-quality decal creation. |

| Finance | Profitable Pricing | A clear pricing model that covers costs and ensures healthy margins. |

| Growth | Marketing & Sales | A targeted strategy to attract and retain your ideal UK clients. |

| Scaling | Expansion & Compliance | A plan for future growth, partnerships, and legal adherence. |

By tackling these key areas one by one, you’re not just starting a hobby; you're building a sustainable and scalable windows decals business. Each stage builds on the last, creating a robust operation ready for anything from small custom orders to large commercial projects.

Let’s get started.

Choosing Your Materials and Equipment

The final quality of your window decals comes down to two things: the materials you use and the machinery that brings your designs to life. When you're starting a windows decals business, getting these core components right from the very beginning is absolutely critical. Smart choices now will save you from costly reprints, unhappy clients, and a whole lot of wasted vinyl down the line.

Your main material, of course, will be self-adhesive vinyl. But it's not a one-size-fits-all game. Understanding the different types is crucial because each one has a specific purpose, lifespan, and price point. Get this wrong, and you could see a decal peeling off a client’s window just weeks after installation – and that’s a reputation killer.

Understanding Your Vinyl Options

Not all vinyl is created equal. You’ll mainly come across three categories: monomeric, polymeric, and cast. Just think of them as 'good, better, and best', each suited for different jobs.

- Monomeric Vinyl: This is your entry-level, budget-friendly choice. It’s perfect for short-term, indoor applications – think a "25% Off Sale" sign for a local shop that will only be up for a few weeks. It's a bit less flexible and can shrink over time, which makes it a poor choice for long-term outdoor use.

- Polymeric Vinyl: Here’s your versatile workhorse. It’s far more durable and stable than monomeric, with an outdoor lifespan of around 5-7 years. It's the ideal middle ground for corporate logos on office doors or semi-permanent branding on a café window.

- Cast Vinyl: This is the premium, top-of-the-line option. It’s made through a different process that makes it incredibly durable, flexible, and easy to shape around curves. For a fleet of commercial vans or high-end storefront branding that needs to look perfect for a decade, cast vinyl is the only way to go.

The key is matching the vinyl to the client’s actual needs. A temporary event doesn't need expensive cast vinyl, just as a permanent architectural feature should never, ever be done with a cheap monomeric film.

Equipping Your Workspace for Success

Once you've got your materials sorted, you need the right tools to turn those rolls of vinyl into polished, professional products. It's tempting to cut corners here, but investing in reliable equipment is non-negotiable if you want to produce top-quality work time and time again.

Your initial setup will centre on a few key pieces of machinery.

A classic mistake new business owners make is underestimating the importance of a good cutter. You can have the best printer in the world, but if your plotter can't accurately cut an intricate design, you'll be left with a frustrating weeding job and a subpar final product.

The demand is definitely there. The UK's printed vinyl market is a big one, generating USD 460.6 million in revenue in 2024. Interestingly, monomeric vinyl—your go-to for many starter jobs—holds the largest market share at 53.99%. That just goes to show how much business there is in short-term promotional work. You can dig into more UK printed vinyl market trends to see where the real opportunities are.

Your essential equipment list should include:

- A Wide-Format Printer: This will be your biggest investment. Look for an eco-solvent or latex printer, as they produce vibrant, durable prints that can stand up to the British weather. Brands like Roland, Mimaki, and HP are industry standards for a good reason.

- A Vinyl Cutter (Plotter): This is the machine that cuts your printed designs with pin-point precision. While many printers have integrated cutting functions, a standalone cutter from a brand like Graphtec or Summa often gives you more power and accuracy for really complex jobs.

- A Laminator: Not essential for every single job, but a laminator is key for adding that extra layer of durability and a professional finish. It protects prints from scratches, UV fading, and moisture, seriously extending the life of your decals.

- Design Software: You can't make great decals without great software. Adobe Illustrator is the undisputed industry benchmark for creating vector graphics, which are vital for crisp, scalable designs. CorelDRAW is another popular and powerful alternative.

This combination of hardware and software is the backbone of your entire production process. For a glimpse of what’s possible with the right setup, check out these custom-shaped weatherproof window stickers.

Starting with reliable, professional-grade equipment—even if it's second-hand—will save you a world of time and money compared to struggling with entry-level hobbyist machines. It's the foundation your business's reputation for quality will be built on.

Mastering Your Production Workflow

You’ve got the right materials and the equipment is fired up. Now comes the real work: turning a digital file into a physical, high-quality window decal. This is where your business really comes to life.

Getting your production workflow right isn't just about churning out orders faster. It's about consistency. A slick, repeatable process is your secret weapon for delivering professional results every single time, turning one-off buyers into loyal customers.

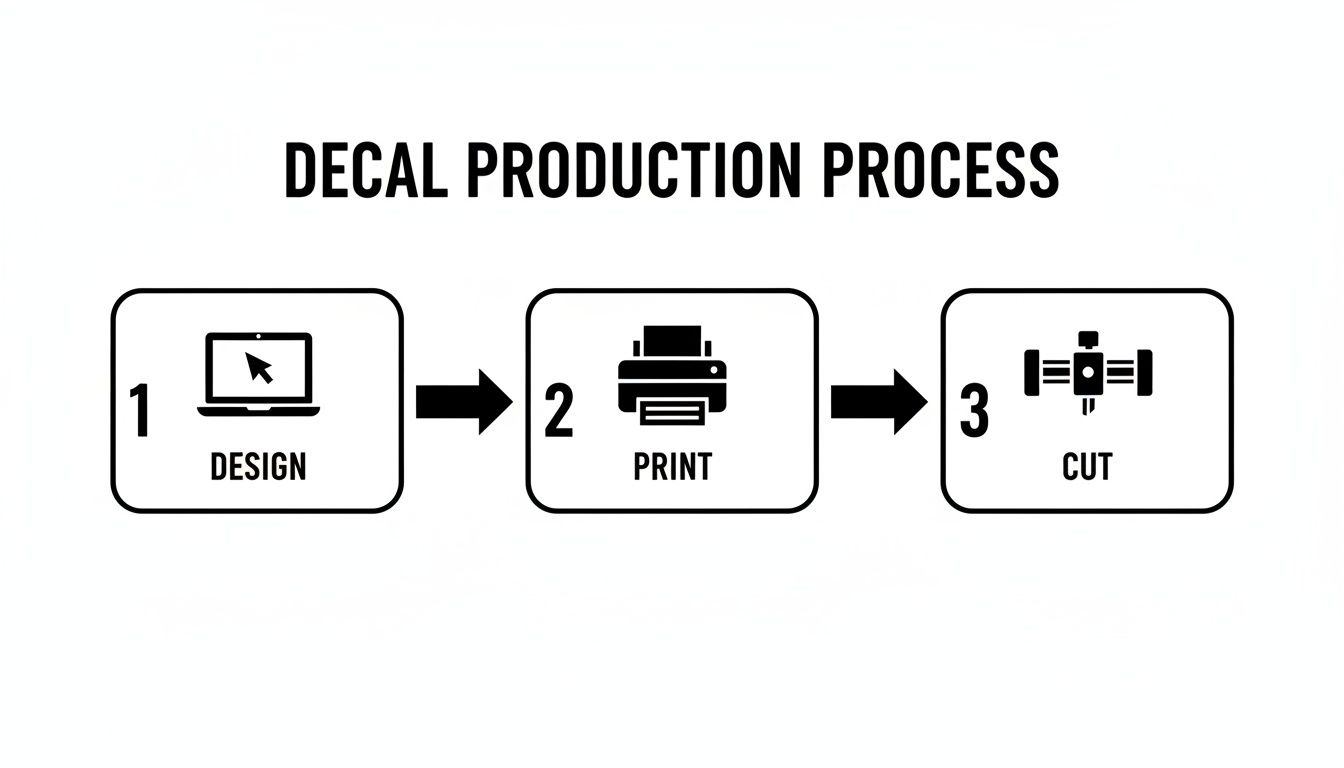

The journey from a customer's design file to a finished decal ready for shipping is a clear, three-stage process: design prep, printing, and cutting.

Nailing each of these steps is what separates the amateurs from the pros. A solid workflow means less wasted vinyl, fewer costly mistakes, and a reputation for being dead-on reliable. It all kicks off the second a customer’s artwork lands in your inbox.

The All-Important Pre-Flight Check

Stop. Before you even think about hitting ‘print’, you need to give the client’s file a thorough pre-flight check. This is your single best chance to spot problems that could wreck the whole job. Rushing this stage is a rookie error that almost always ends in pixelated prints, dodgy colours, or cuts that are completely off.

Your checklist should cover a few non-negotiables:

- File Format: Is it a vector file? You're looking for formats like .AI, .EPS, or .SVG. These can be scaled up to any size without losing a shred of quality—absolutely essential for a huge shop window graphic. A low-res JPEG just won't cut it.

- Colour Profile: The file needs to be set to CMYK (Cyan, Magenta, Yellow, Key/Black). This is the standard for professional printing. If a client sends an RGB file (meant for screens), the colours can shift dramatically when printed, leading to some very unhappy customers.

- Cut Lines: Look for a clean, clearly defined cut line. This is usually a vector path set with a unique spot colour that tells your plotter precisely where to slice. Without it, the machine is flying blind.

- Bleed & Margins: If the design prints right to the edge, it must have a bleed – typically 3-5mm. This little bit of extra background colour is a safety net, preventing ugly white slivers from showing up if the cut is off by a hair's breadth.

Once the file gets the green light, it’s ready for your RIP (Raster Image Processor) software. Think of the RIP as the translator between your design and your printer, managing colour and prepping the file for a perfect print.

From Print to Precision Cut

With the file prepped, it's time to make something tangible. Load your chosen vinyl into the printer and send the job. Don't just use default settings; pay close attention to the recommended heat and ink levels for the specific material you’re using. Getting this right makes a huge difference to the final quality.

After printing comes the cut. If you're running an integrated printer/cutter, the machine takes care of this seamlessly. If you have separate machines, you’ll move the printed roll over to your plotter. The cutter uses printed registration marks—small dots or squares—to align itself perfectly, ensuring the cut follows the design with pinpoint accuracy.

The accuracy of your cutter is everything. A high-quality plotter can handle incredibly fiddly designs with sharp, clean lines. A cheaper model might struggle, tearing the vinyl or rounding off corners, which instantly cheapens the look.

The Art of Weeding and Finishing

Once cut, the decal moves to the most hands-on part of the job: weeding. This is the delicate process of removing all the unwanted vinyl around your design, leaving just the decal on its backing paper.

Depending on the design, weeding can be either a zen-like task or a true test of your patience. A simple shape is a breeze, but a logo with intricate lettering requires a steady hand and good lighting. Specialist tools like a weeding hook or precision tweezers are your best friends here.

For that extra professional touch and added durability, lamination is your final step. Applying a clear laminate over the print protects it from scratches, moisture, and UV rays that cause fading. It's a must for decals that will live on vehicles or sun-drenched shopfronts.

Finally, apply application tape over the top of the weeded decal. This tape holds all the individual parts of the design together, making it simple for your client to apply the whole thing in one go. Get this workflow down, and every decal that leaves your workshop will be something you’re proud to put your name on.

Nailing Your Pricing Strategy

Right, let's talk about money. Getting your pricing right is probably the most critical part of running a profitable decals business. It's a classic balancing act. Go in too high, and you’ll struggle to win jobs. Go in too low, and you'll be running on fumes, working all hours for pennies. That’s a one-way ticket to burnout.

Forget plucking numbers out of thin air. A solid pricing strategy is built on knowing your numbers inside and out. You need a crystal-clear picture of what it costs you to produce a decal before you can even think about what to charge. This is your foundation for building a business that’s fair to your customers and, just as importantly, financially healthy for you.

Calculating Your Core Costs

The most straightforward way to get started is with a cost-plus pricing model. It’s simple: you work out your total costs for a job and then add your profit margin on top. This method is transparent and makes sure you’re not accidentally losing money on an order.

To do this properly, you need to break down every single cost involved in making a decal, right down to the square metre.

- Vinyl Cost: This is your biggest material expense. Know exactly what you pay per square metre for the specific vinyl you’re using.

- Ink and Consumables: Printers drink ink and use cleaning fluids. It's tricky to measure this per job, but you can work out a good estimate by dividing your average monthly consumable costs by your typical output.

- Electricity: Your printer, cutter, and laminator all need power. Again, work out a rough cost per hour of operation and factor it in.

- Your Labour: This is the big one people forget. Pay yourself! Set a realistic hourly rate for your time and track how long a job actually takes – from setting up the file and printing to the fiddly bits like weeding and packing.

Once you’ve tallied these up, you’ll have your baseline production cost per square metre. This is your break-even number. Anything on top of that is your profit.

A rookie error is to only calculate the cost of the vinyl that ends up on the final decal. You have to account for wastage – the offcuts and the bits left on the roll. A smart move is to add a 10-15% buffer to your material costs to cover this.

Pricing for Value and Complexity

Here’s the thing: not all decals are created equal. A simple, one-metre square is a world away from a sheet of tiny, intricate letters that takes an hour of painstaking weeding. Your pricing has to reflect that extra effort.

This is where you move beyond a simple cost-plus model and start pricing for the value and complexity you provide.

- Design Services: If a client sends you a perfect, print-ready vector file, great. But what if they give you a fuzzy JPEG and ask you to "make it work"? That's a separate design job. Charge an hourly rate for any artwork creation or file fixing.

- Weeding Complexity: For really fiddly designs, you need to add a "complexity fee" or simply increase your labour charge. Time yourself on a few complex jobs to see how much longer they genuinely take compared to the easy ones.

- Installation: Offering an installation service is a brilliant way to add a huge amount of value and seriously boost your margins. Price this separately based on the job size, location, and how tricky the surface is to work with.

By itemising these elements, you’re not just covering your costs – you’re showing the client the true value of the professional service you’re providing.

Sample Pricing Calculation Per Square Metre

Let's break it down with a real-world example. Here’s a simplified calculation for a standard polymeric vinyl decal, where we're aiming for a healthy profit margin.

| Cost Component | Example Cost | Notes |

|---|---|---|

| Polymeric Vinyl (inc. wastage) | £8.00 | Your cost per square metre from your supplier. |

| Ink & Consumables | £2.50 | An estimated cost based on average machine usage. |

| Electricity & Overheads | £1.00 | A small charge to cover workshop running costs. |

| Labour (20 mins @ £20/hr) | £6.67 | Time for setup, printing, weeding, and finishing. |

| Total Cost to Produce | £18.17 | This is your break-even point for one square metre. |

| Profit Margin (e.g., 100%) | + £18.17 | Your desired markup to ensure profitability. |

| Final Price to Customer | £36.34 | This is your retail price, excluding VAT. |

This table makes it clear how you get from your direct costs to a final retail price. You can tweak your markup to stay competitive, but this structure guarantees that every single sale is making you money and helping your business grow.

Marketing and Selling Your Window Decals

Creating incredible decals is one thing, but getting them into the hands of paying customers is where the real work begins. To build a thriving windows decals business, you need a smart, focused marketing strategy. Forget trying to be everywhere at once; your success will come from targeting the right people, in the right places, with the right message.

This isn't about sinking money into complex, expensive campaigns. It's about taking practical, effective steps that work for a UK startup. The goal is simple: connect with local businesses who need exactly what you’re selling.

Building Your Digital Shopfront

Before you spend a penny on ads, your online presence needs to be sorted. Think of it as your digital portfolio and your number one sales tool. A clean, professional online space builds instant trust with potential clients.

Instagram is the perfect place to start. It’s a visual platform, making it ideal for showing off your work. Set up a dedicated business account and start posting high-quality photos and videos of your best projects. Show the design process, the application, and the stunning final result. Use hashtags like #WindowGraphicsUK, #ShopfrontDesign, and #VinylDecals to get in front of businesses looking for inspiration.

Next, you need a simple but professional website. It doesn't need all the bells and whistles. Just focus on the essentials:

- A Gallery: This is your hero section. Fill it with brilliant photos of your completed projects.

- Services: Clearly outline what you do—custom designs, installation, frosted vinyl, etc.

- About Us: A short section to tell your story and build a personal connection.

- Contact Form: Make it incredibly easy for potential customers to request a quote.

Your online portfolio is your most powerful sales tool. A potential client is far more likely to be convinced by a stunning photo of a completed project than by a lengthy written description. Let your work do the talking.

Winning with Local Marketing

While a strong online presence is essential, your best opportunities are probably right on your doorstep. Local businesses are the lifeblood of any new decals company. They need signage, promotional displays, and branding, and most prefer to work with a reliable local supplier.

First, think about who your ideal local clients are. Who needs window decals?

- Retail Shops for sales, seasonal promotions, and branding.

- Cafes & Restaurants for menus, opening hours, and special offers.

- Estate Agents for property listings and office branding.

- Construction Firms for site safety info and branding on hoardings.

- Event Organisers for temporary branding at local markets and festivals.

Make a list and start getting out there. Walk into local shops, introduce yourself, and leave a business card or a small sample. Go to local business networking events. Your aim is to become the go-to name for window graphics in your area.

The demand is definitely there. The broader UK vinyl decal market is booming, partly driven by what's happening in other sectors. Take the European car decal market, where the UK holds a significant 20.60% share. This shows a wider trend of UK businesses embracing vinyl for all kinds of branding. As high street shops fight to compete with e-commerce, they're refreshing their window displays 20-30% more frequently, creating consistent demand for quick, quality decal services.

Becoming the Go-To Supplier

Fantastic customer service and a fast, reliable turnaround will make you stand out. In this game, speed is a huge advantage. A shop manager planning a last-minute flash sale needs their decals now, not next week. If you can deliver quality work on a tight deadline, you'll earn their loyalty for good.

Always be clear in your communications, provide accurate quotes, and deliver on your promises. A happy customer is your best marketing tool—they’ll come back, and they’ll recommend you to others. For a deeper dive into marketing essentials, check out this practical guide to marketing for small businesses.

Finally, think beyond just selling a product. Sell a solution. A café owner might not know exactly what they want, but they know they need more customers. You can be the one to suggest creative ideas that grab attention. Our guide on https://bannerprintingltd.co.uk/shop-window-display-ideas/ is packed with inspiration you can adapt for your clients. By positioning yourself as a knowledgeable partner instead of just a printer, you’ll build stronger, more profitable relationships.

Taking Your Decals Business to the Next Level

Once your order book is consistently full and your name is getting out there, you'll hit a turning point. Growth stops being an aspiration and becomes a necessity. But scaling successfully isn’t just about churning out more decals; it’s about working smarter, upgrading your kit, and planning ahead so you can expand without letting that quality slip.

So, how do you know it's time? The signs are usually pretty clear. Are you reluctantly turning away bigger, more profitable jobs because your printer can’t handle the width? Is all your time getting sucked up by weeding tiny, intricate designs, leaving no time to find new customers? These are your cues to invest. This might mean getting that wider, faster printer/cutter you've been eyeing up, bringing in some software to manage your workflow, or even taking the leap and hiring your first pair of hands.

Partnering Up for the Big Jobs

Here’s a secret: you don’t have to do it all yourself. One of the smartest ways to grow is by teaming up with others.

Imagine a national retail chain wants a quote for decals across 50 of their UK stores. Your current setup would buckle under the pressure. This is where a partnership with a large-format trade printer becomes your secret weapon. They have the industrial-scale machinery to handle huge print runs, letting you take on those lucrative contracts without the eye-watering cost of buying the equipment yourself.

With this model, you get to say "yes" to those game-changing opportunities. You become the project manager, using the firepower of a specialist partner to get the job done. It’s a brilliant, low-risk way to dip your toes into the world of major commercial work.

Staying on the Right Side of the Law

Growth comes with a bit more paperwork, but getting your legal ducks in a row early on is crucial for building a professional, trustworthy business.

Here are the key things you need to have sorted in the UK:

- Registering Your Business: First things first, you need to register with HMRC. You can start as a sole trader—it’s the simplest way to get going. Or, you can set up a limited company, which gives you more protection if things go wrong.

- The VAT Question: Once your taxable turnover hits the government’s threshold (currently £90,000 a year), you must register for VAT. This means you'll add VAT to your prices, but you can also claim back the VAT on things you buy for the business.

- Getting Insured: Public liability insurance is a must-have. It covers you if your work accidentally causes an injury or damages a client’s property—say, a decal installation goes wrong. If you hire anyone, even part-time, you're legally required to have employer's liability insurance.

A safe workshop is non-negotiable. Always make sure you have good ventilation, especially if you're using solvent-based inks. And store your chemicals, like cleaning fluids, correctly according to COSHH (Control of Substances Hazardous to Health) rules. It’s about protecting yourself and anyone who works with you.

As you start marketing more widely, compliance becomes even more important. If you decide to try SMS marketing, for example, you need to know the rules. This SMS Marketing Compliance: Legal Success Guide is a great resource for understanding the legal side of things. Get proactive with compliance, and you can scale your business with total confidence.

Common Questions About Starting a Decals Business

Jumping into a new business venture always sparks a few questions. When you're launching a window decals business, you’ll face your own unique set of challenges and opportunities. Let’s tackle some of the most common queries to give you a clear path forward.

First up, is it actually profitable? The short answer is yes, but it all comes down to your strategy. While your margins depend on pricing and how efficiently you work, the UK market has a solid demand for decals. A well-run business can be very profitable if you source your materials wisely and focus on high-value services like design and installation, especially when you’re the go-to for local businesses needing regular promotional updates.

Another big worry is what happens when things go wrong. What if a decal is applied with a few too many bubbles, or a client has a last-minute change of heart? For starters, always get a proof approved before you print a single thing – it saves so many headaches. As for application, practice makes perfect. If a customer needs an old graphic stripped off, knowing the right way to do it is a massive plus. We've got some great advice in our guide on removing sticker residue from glass without damaging the surface.

What Is the Most Important Initial Investment?

Without a doubt, your printer and cutter. It’s the heart of your entire operation.

While it’s tempting to save a few quid with a cheaper, hobby-level machine, it's a false economy. Professional-grade equipment from brands like Roland or Mimaki delivers the reliability and precision you need to produce top-notch results every single time. A quality machine cuts down on wasted vinyl, breezes through complex jobs, and helps you build a reputation for excellence from day one.

Your equipment is the foundation of your business. Investing in a reliable, professional-grade machine isn’t just an expense; it’s a direct investment in the quality of your product and your long-term reputation. Skimping here will cost you far more in reprints, wasted time, and lost customers down the line.

Ready to scale up or need a hand with a large project? The team at Banner Printing Ltd offers expert large-format printing services to support your growing business. https://bannerprintingltd.co.uk